E-Coating

- Superior Industrial Coating has the capability to:

- E-Coat Millions of Parts

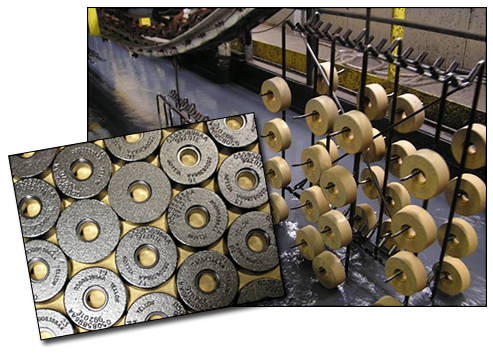

- Process 50 Sq Ft of Product per Minute

- Coat from .5 to 1.5 mil Thickness

- Test and Certify Thickness

- Salt Spray Parts per Your Spec

E-Coating The Superior Way

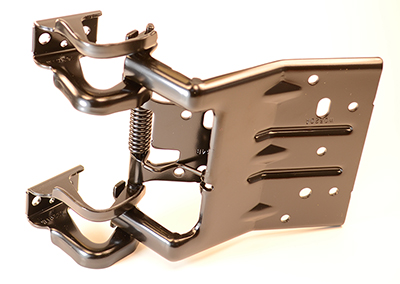

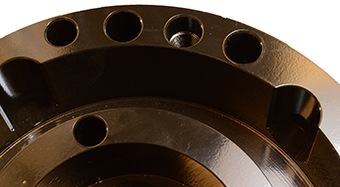

While most electrodeposition coating companies use a process called indexing, Superior's monorail e-coating system truly is superior. Our monorail system allows the coating to penetrate into cavities in the part. The parts are coated more thoroughly, resulting in a superior, consistent finish, as well as superior durability. The monorail system is also the state of the art in efficiency. That's why it's used by leading manufacturers in the automotive and electronic industries, such as Mercedes Benz, Ferrari, Hewlett-Packard, and Sony just to name a few. Parts remain on the monorail through every stage: Cleaning; Pretreatment; Coating; Rinsing; Dehydration; Curing; and on to Loading. The result? A superior coating at an economical price.

Why Doesn't Everyone Coat This Way?

Monorail systems take up a lot of space. Most e-coaters just don't have our 215,000 square feet to work with. This gives us a distinct advantage, which means that it gives you a distinct advantage too.

E-Coating That's Consistently Higher Quality

You want an e-coating company that delivers consistent quality. Our customers tell us that's why they keep coming back to Superior Industrial Coating. They know they won't get a couple of good lots and then a bad lot. Every batch of parts is coated to the same high standards.

E-Coating Without Shrinkage

There is little that's more frustrating than not getting all of your parts back. At SIC we care for your parts as if they were our own.

E-Coating At The Right Price

Being located in low-overhead Racine, Wisconsin, allows us to deliver quality coating at a great price.

Request a quote.

E-Coating With Quick Turn Around

Your e-coating project will be turned around and back to you quickly due to our efficient facility and systems.

E-Coating From Prep To Coating, To Assembly, To Packaging

We are your One Stop Finishing Shop.

- Consistent Quality With No Shrinkage

- Priced Right

- Quick Turn Around

- One Stop Finishing

- Partial Coating or Full Coating

- From the Smallest Clips to the Largest Castings

E-Coating Wisconsin, Illinois, North America, Europe

Located in Racine, Wisconsin, we serve customers in Wisconsin and Illinois as well as throughout North America and Europe.

E-Coating Expertise

Just because e-coating is relatively inexpensive, doesn't mean that you shouldn't look for a quality e-coating vendor. Superior Industrial Coating's Cathodic Black Epoxy E-Coating is backed by years of experience and will result in a finished product that's lower in cost but not lower in quality.

Electro-Deposition Coating

E-coating, or electro-deposition coating, is a process by which a metallic part is immersed into a paint/water bath with electrically charged particles, where the electricity is then utilized in the deposition of the paint onto the part. E-coating works with magnesium, aluminum, zinc, brass, steel, or any material that conducts electricity. E-coating is "short" for electro-deposition coating, which is also sometimes referred to as electro deposition coating (without the hyphen) or electrodeposition coating. However you say it, e-coating is a cost effective and durable finishing solution.

E-Coating Is Cost Effective Yet Corrosion Resistant

E-Coating is the most automatic, controllable, and efficient method for applying a corrosion inhibiting primer to a metallic part. E-coating was developed originally for the automotive industry because it is economical and provides superior coverage, adhesion and corrosion resistance. It is now used in many other industries such as Agriculture, Medical, and Electronics as well. E-Coating delivers the highest level of productivity at the lowest cost. Contact us today to let our coating engineers review your project to determine if e-coating is the right solution for your particular application.

We also do Powder Coating and Wet Coating.